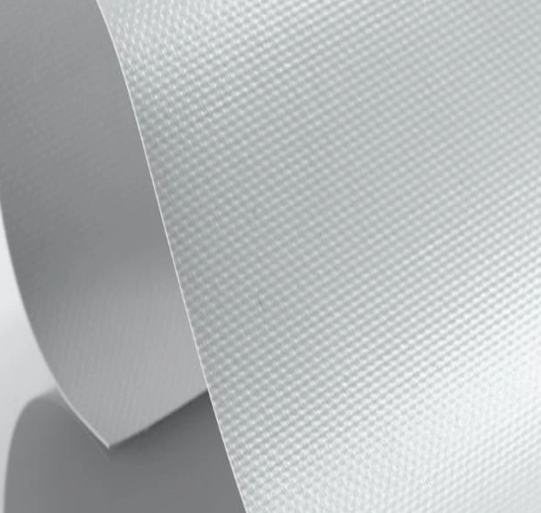

Flex banner is commonly used in our daily life and is one of the most widely used material in advertising industry. It varies from one type to another in different application fields, and the price of it is also different. What’s more, the classification of flex banners is decided by its production process, do you know about the production process?

(Application)

There are three mainly production process about flex banners: coated, hot laminated and cold laminated, let ‘s make a detailed introduction about them.

First, the coated process.

The liquid PVC will be poured on the cloth evenly, and then be scraped steadily on it. After cooled, they will be an integrated whole. It is characterized by strong anti-permeability, tensile strength, and anti-stripping ability. Because the two layers is strictly put together, the peeling phenomenon can be effectively eliminated. At present, the width of flex banners can reach 5 meters. Because of the complicated manufacturing process and expensive manufacturing equipment, such kinds of products are mainly imported in the Chinese market, and the price is relatively high. The most representative companies are the Germany Ultron, South Korean UNIFLEX and Belgium (SIOEN).

Second, the hot laminated process.

Mix fully PVC powder and various raw materials up such as liquid plasticizer, and then adhere to the base fabric into a whole by the pressure action of a high-temperature hot roller. It is characterized by good surface flatness, great light transmission, and the advantages of backlit. However, due to equipment limitations, the width of it generally does not exceed 3 meters. The 645 and 945 flex banners developed by 3M Company in the United States are produced by this process. Another South Korean LG company developed the Lexi flex banner is also a representative of this kind of technology.

Third, the cold laminated process.

Put the two layers of PVC film separately on and under the basic clot and then make them all heated and bonded under the pressure of a hot roller, and then cooled and formed. This kind of process is characterized by excellent ink absorption and strong color expression. Therefore, along with the rise of large-scale inkjet printing, this kind of flex banner has brought infinite vitality in this field, taking more than 70% market share in Chinese market.

Post time: Nov-17-2022